091-5758564, 081-6679233 ,02 7035192

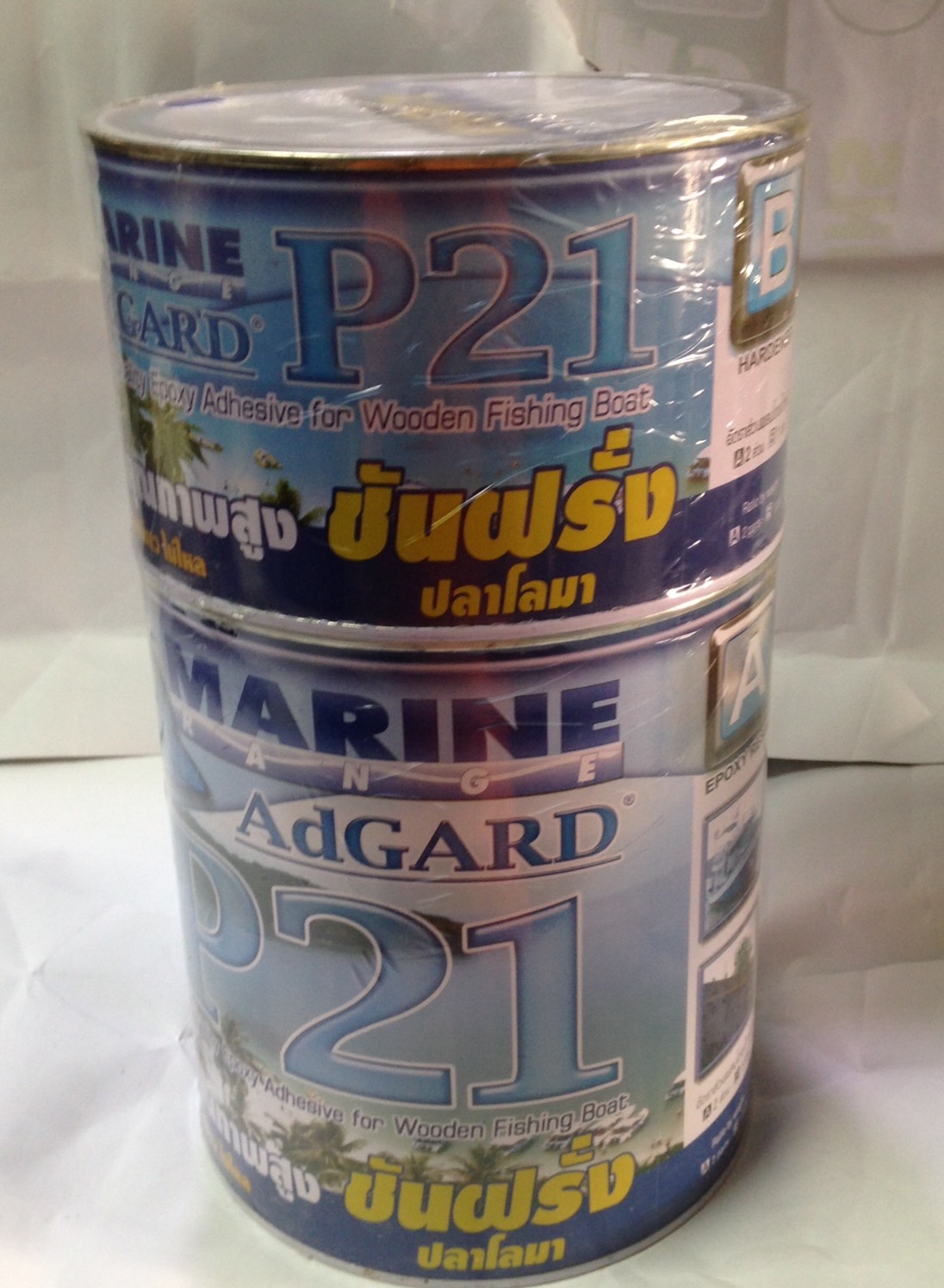

AdGARD P21AdGARD P21

Premium Quality Epoxy Adhesive Putty

Description P21 is a premium quality, 2-componebt epoxy adhesive putty specially formulated with a high grad epoxy resin, hardener, and special selected reinforced materials. Its consistency paste allows easy applying into big gaps, joints, or holes.

Use and Advantage

AdGARD P21 provides excellent adhesion, no shrinkage, no sag, consistency paste, and decorative and smooth surface texture. Because of the excellent properties of structural grade filler, putty like, and high strength adhesive. AdGARD P21 can be widely used for both new wooden boat building (filling gap, caulking, bonding, putty like, combination use with mechanical fixing for structural part or support etc.) and repairing. This product can be used as an adhesive in many industrial and construction applications.

Specification

After Mixing ( A+B=2:1 by weight) A2K : B4K

Pot life 40-45 minutes at room temperature

Gel time 35-40 minutes

Thin film set 5-6 hours

Full cure 24 hours at room temperature

Hardness Shore D 85

Water adsorption 0.08% (ASTM D 570)

NOT: Water absorption at 50% C for 24h.

The time is varied depending on application, environment humidity, and temperature.

Applications

- The mixing ratio between part A and part B =2:1 by weight

- For small quantity, maxing with a mixing paddle at low speed at least 5-8 minutes until uniform color and is obtained.

- Product must be applied before gel time.

Instruction for use

1. Surface must be clean, dry, and sound. Remove dust grit, oil, grease, or other contaminant materials.

2. For wooden boat caulking or filling, fill oakum into a gap or joint at the proper depth(If the joint width is more than 10mm, the joint depth should be a half of the joint width. Is less than 10mm, the joint depth should be equal to the joint width). Do not soak oakum with wood tar, solvent, or paint, since it may cause an adhesion failure on wood and substrate. If the waterproof and priming finish on wood us needed, apply AdGARD WC 31 to form a very thon film that can penetrate through the wood grain.

3. Mixing the 2 parts according to the above instruction of application tips.

4. Apply the excess adhesive by spatula in a continuous steady flow until the gap is completely filled. Remove the excess adhesive. Tool immediately after application, remove masking, and clean the adhesive before the adhesive gel time with thinner A1

5. Application temperature – 10![]() C to 40

C to 40![]() C

C

Storage

The adhesive should be stored in a dry and cool place. The shelf life is a at least 12 months in original and un-opened package from date of manufacture.

Limitations Do not use for PE, PP, PTFE and some kind of plastics.

Safety

The product contains epoxy resin and complex polyamine hardener. It may cause severe eye and skin irritation.

Avoid prolonged contact, with eyes and skin.

In case of contact, flush with high amount of water and seek medical attention immediately.

In case of skin contact, wipe off and wash with soap and water.

AdGARD P21AdGARD P21

Premium Quality Epoxy Adhesive Putty

Description P21 is a premium quality, 2-componebt epoxy adhesive putty specially formulated with a high grad epoxy resin, hardener, and special selected reinforced materials. Its consistency paste allows easy applying into big gaps, joints, or holes.

Use and Advantage

AdGARD P21 provides excellent adhesion, no shrinkage, no sag, consistency paste, and decorative and smooth surface texture. Because of the excellent properties of structural grade filler, putty like, and high strength adhesive. AdGARD P21 can be widely used for both new wooden boat building (filling gap, caulking, bonding, putty like, combination use with mechanical fixing for structural part or support etc.) and repairing. This product can be used as an adhesive in many industrial and construction applications.

Specification

After Mixing ( A+B=2:1 by weight) A2K : B4K

Pot life 40-45 minutes at room temperature

Gel time 35-40 minutes

Thin film set 5-6 hours

Full cure 24 hours at room temperature

Hardness Shore D 85

Water adsorption 0.08% (ASTM D 570)

NOT: Water absorption at 50% C for 24h.

The time is varied depending on application, environment humidity, and temperature.

Applications

- The mixing ratio between part A and part B =2:1 by weight

- For small quantity, maxing with a mixing paddle at low speed at least 5-8 minutes until uniform color and is obtained.

- Product must be applied before gel time.

Instruction for use

1. Surface must be clean, dry, and sound. Remove dust grit, oil, grease, or other contaminant materials.

2. For wooden boat caulking or filling, fill oakum into a gap or joint at the proper depth(If the joint width is more than 10mm, the joint depth should be a half of the joint width. Is less than 10mm, the joint depth should be equal to the joint width). Do not soak oakum with wood tar, solvent, or paint, since it may cause an adhesion failure on wood and substrate. If the waterproof and priming finish on wood us needed, apply AdGARD WC 31 to form a very thon film that can penetrate through the wood grain.

3. Mixing the 2 parts according to the above instruction of application tips.

4. Apply the excess adhesive by spatula in a continuous steady flow until the gap is completely filled. Remove the excess adhesive. Tool immediately after application, remove masking, and clean the adhesive before the adhesive gel time with thinner A1

5. Application temperature – 10![]() C to 40

C to 40![]() C

C

Storage

The adhesive should be stored in a dry and cool place. The shelf life is a at least 12 months in original and un-opened package from date of manufacture.

Limitations Do not use for PE, PP, PTFE and some kind of plastics.

Safety

The product contains epoxy resin and complex polyamine hardener. It may cause severe eye and skin irritation.

Avoid prolonged contact, with eyes and skin.

In case of contact, flush with high amount of water and seek medical attention immediately.

In case of skin contact, wipe off and wash with soap and water.

|

สินค้าที่เกี่ยวข้อง

สินค้าที่เกี่ยวข้อง